Construction sites and, especially, demolition sites are often challenging environments for surveyors. Nevertheless, effective project management and financial control depend on accurate and timely information about the volumes of materials which have been placed, relocated and removed. Conventional surveys to obtain this information are slow, labour intensive, expose surveyors to danger and can disrupt site operations. Photogrammetry using an Unmanned Aerial Vehicle (UAV or drone) and the 3Dsurvey software suite offers an efficient, cheaper and safer alternative.

PROJECT DESCRIPTION

The demolition of a large power station in Germany required effective work progress monitoring, identification of the materials on site, and determination of volumes. The site covered approximately 40 ha and the buildings had a combined volume of approximately one million cubic metres. Conventional surveying methods would have been extremely time-consuming, exposed the surveyors to a hazardous environment and not have provided sufficiently detailed data.

Problem

The area of the demolition site is very large, about 400,000 m², and the volume of the buildings is around 1,000,000 m³. Traditional single-point shooting would be extremely time-consuming and could create too many single-points. The progress of the demolition had to be recognizable to the client who is not an engineer. The presentation of the results using a 3D site plan was not sufficient for the client.

Approach

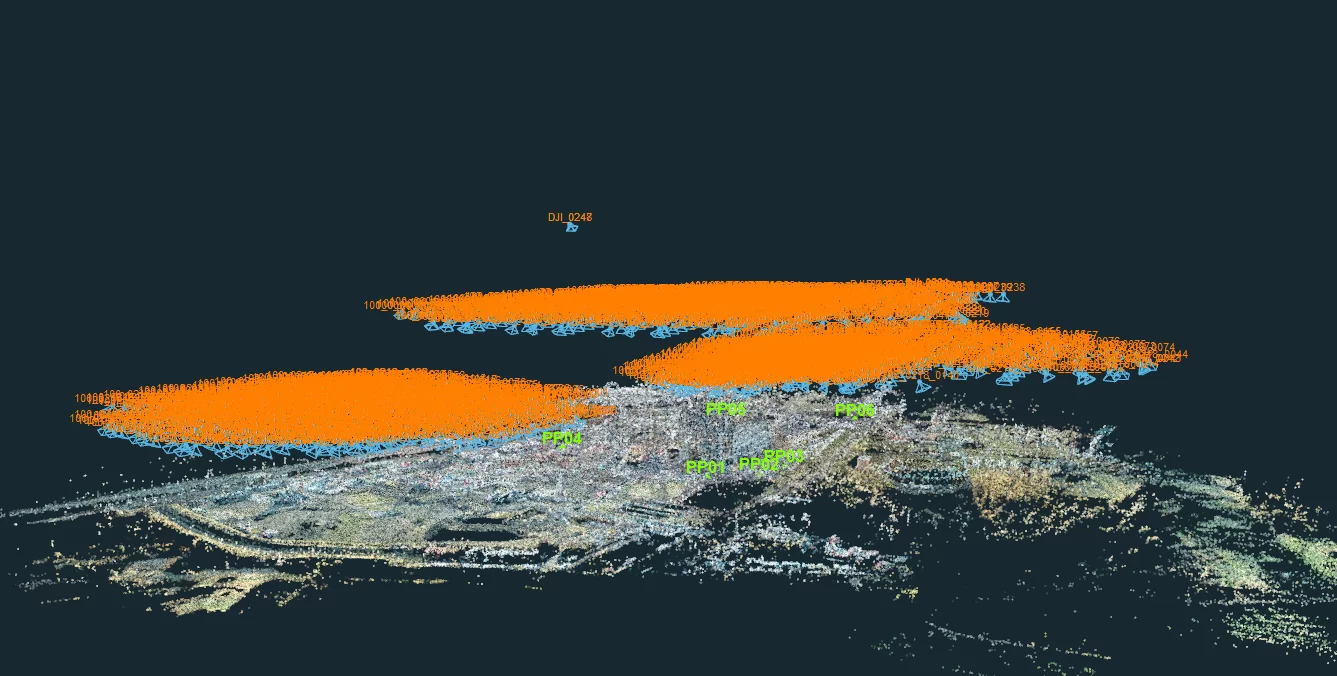

The surveying team decided to undertake regular photogrammetric surveys using a UAV (DJI P4 RTK), a GNSS receiver (Emlid Reach RS2) and the 3Dsurvey software. The initial survey of the wider area (approx. 2000 images) was followed by monthly surveys of the demolition area (approx. 1000 images) to determine progress. For each survey the positions of several ground control points (GCPs) were determined using the GNSS receiver. Using a UAV with RTK significantly reduced the number of GCPs required. For applications demanding less accuracy, surveys can even be done without any GCPs. Surveyors can use any convenient type of GCP, or dedicated 3Dsurvey GCP targets which are automatically recognised by the software, to save even more time.

The surveying team decided to undertake regular photogrammetric surveys using a UAV (DJI P4 RTK), a GNSS receiver (Emlid Reach RS2) and the 3Dsurvey software. The initial survey of the wider area (approx. 2000 images) was followed by monthly surveys of the demolition area (approx. 1000 images) to determine progress. For each survey the positions of several ground control points (GCPs) were determined using the GNSS receiver. Using a UAV with RTK significantly reduced the number of GCPs required. For applications demanding less accuracy, surveys can even be done without any GCPs. Surveyors can use any convenient type of GCP, or dedicated 3Dsurvey GCP targets which are automatically recognised by the software, to save even more time.

The flight was prepared with 3Dsurvey Pilot, the free app for planning flights with DJI UAVs.

Solution

This project used only UAV photographs, but for other applications these can be combined with images from ground-based cameras, LIDAR and sonar. After the flight the photographs were imported into the 3Dsurvey software and linked to the GCPs with the Orientate function. Next, the software generated the point cloud, full 3D mesh, Digital Surface Model (DSM) and true orthophoto. The resolution of the images was high enough for effective identification of the materials to be removed from site.

TOOLS & SPECS:

Type: Documentation of deconstruction progress

Area: approx. 400,000 m²

Volume: over 1,000,000 m³

Drone: DJI Phantom 4 RTK

Period: August 2020 – February 2021

Location: West Germany

Measurement and analysis

Once the mesh was created, features such as buildings and heaps of material could be defined and named, and their volume or area calculated. This made it particularly easy to report on the progress of the demolition and waste volumes. 3Dsurvey could also have generated contour maps and site profiles at user-specified intervals. The software has basic CAD functions to draw areas and volumes, which can be exported in DXF and other formats. Undertaking both photogrammetric processing and analysis and measurement within the same software package saved time and costs and reduced errors.

Data presentation and export

The information was presented to the client in a range of formats: a video file with a simulated flight around the site, 2D site plan, 3D model and numerical information to track progress. The 3Dsurvey package exports data in a wide range of file types, such as PDF, DXF, JPEG and TIFF, KMZ for Google Earth, various mapping and GIS formats, and TXT. The client could open the original project file using the free 3Dsurvey Viewer, enabling them to choose from a range of views.

X-ray function looks through roofs

3Dsurvey has a unique feature, the X-ray function. This uses data from a number of photographs taken at different angles to mark wall positions on an orthophotograph, irrespective of the roof overhang. In this way the volume of the buildings can be determined accurately, and drawn with the built-in CAD function. This avoids the need to survey the positions of building corners using conventional methods. The X-ray function can save a lot of time and effort, especially in complex and challenging settings such as this demolition site.

RESULTS

- 3D model in OBJ format – standard 3D format

- Orthophoto map in JPG and KMZ ready for Google Earth

- CAD lines in DXF

- Short videos from 3Dsurvey to compare the area for the client.

BENEFITS

- lower the costs of projects and increase productivity

- add value to the construction project

- provide real-time data information

- significant improvement in surveying accuracy

- drones can fly in inaccessible and hazardous areas

- X-ray function was in this case, due to the difficulty of interlocking buildings, the only way to efficiently obtain the building perimeters for the future calculation of volumes

Conclusion

The combination of a UAV, GNSS receiver and 3Dsurvey software made it possible to complete the initial map, drawings and photographs of the demolition site quickly and safely. This was followed by regular UAV flights to report on the progress of the project. The software provided a range of accurate and valuable project management information at relatively little effort and cost.

Want to know how this project was done? Watch the on-demand webinar in the German language, or a special on-demand webinar on X-ray feature.